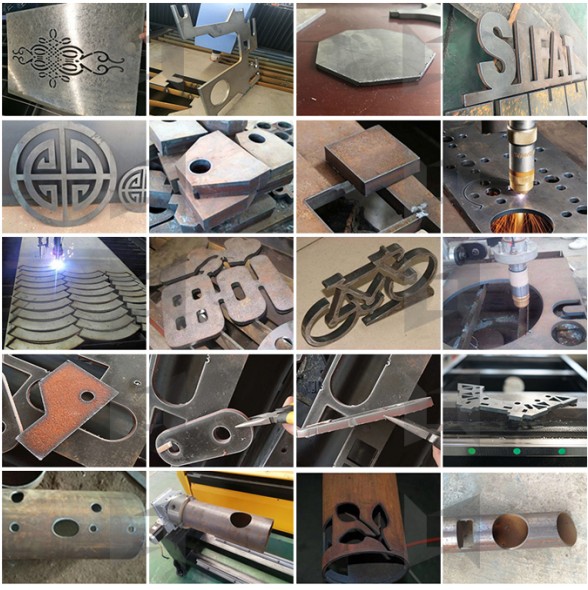

8 Axis Pipe Tube Plasma / Flame Cutting & Beveling Machine

Product Features :

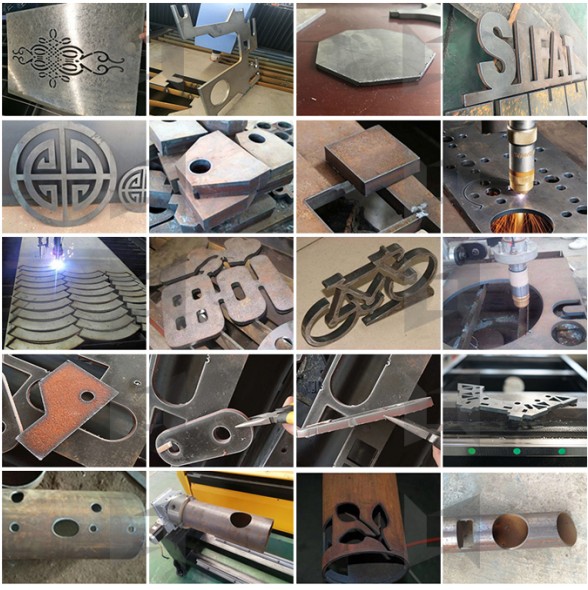

1. Realize the function of beveling, the cutting pipe diameter range is 200-50mm, and the cutting pipe length range is 6m 2. Professional cutting of irregular pipes such as square pipes, round pipes and rectangular pipes, as well as irregular profiles such as H-beam, channel steel and concave steel. 3. The model is beautiful in appearance, compact in structure, stable in operation and easy in operation.

6000mm/200mm CNC intersecting wire cutting machine is a high-efficiency and high-precision automatic pipe cutting equipment, mainly used for cutting various low-carbon steel, stainless steel, copper, aluminum and other pipes. It can cut the end face of round pipe, the intersection of round pipe and plane, and the intersection of various round pipes and round pipes, round pipes and spherical round pipes and curved surfaces, H-shaped steel channels, rectangular pipes, and square pipes. The model is beautiful in appearance, compact in structure, stable in operation and easy in operation. The cutting pipe diameter range is 200-50mm, and the cutting pipe length range is 6m.

Product Features :

6000mm/200mm CNC intersecting wire cutting machine is a high-efficiency and high-precision automatic pipe cutting equipment, mainly used for cutting various low-carbon steel, stainless steel, copper, aluminum and other pipes. It can cut the end face of round pipe, the intersection of round pipe and plane, and the intersection of various round pipes and round pipes, round pipes and spherical round pipes and curved surfaces, H-shaped steel channels, rectangular pipes, and square pipes. The model is beautiful in appearance, compact in structure, stable in operation and easy in operation. The cutting pipe diameter range is 200-50mm, and the cutting pipe length range is 6m.

The mechanical part of the machine is mainly composed of a worktable, a power chuck and a cutting head. The worktable and the power chuck are designed as a whole and processed through the whole machine, so that the longitudinal guide rail and the axis line of the power chuck are kept parallel, which greatly improves the working accuracy of the machine. Two parallel linear guide rails are installed on the side of the worktable, and a precision rack is installed between the guide rails. The drive system on the moving body drives the gear to rotate, realizing the longitudinal gear and rack transmission. The power chuck drives the chuck to rotate through the servo motor and the synchronous pulley, and the chuck drives the workpiece to realize forward and reverse rotation. The cutting head is controlled by dual servo motors, which can do axial and radial deflection. The linkage of these motion axes is controlled by the system to realize the cutting of the intersecting lines of the pipes.

The rotating device of the machine adopts two sets of parallel multi-group chucks to drive. When working, you only need to directly hoist the pipe to the working platform, and use the two sets of chucks to automatically determine the axis of the pipe, so that the pipe can be loaded and unloaded very convenient.